Analysis of Materials Used by Obaili in Insulated Bags

Insulated bags are crucial in daily life, from keeping picnic food warm to transporting temperature sensitive items. Their performance hinges on construction materials. This article explores these materials in terms of insulation, environmental friendliness, durability, and waterproofing, spotlighting Obaili Factory's expertise in crafting high quality insulated bags.

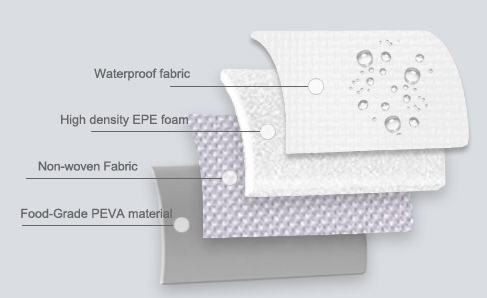

First, Insulation Materials

Traditional Options

· Pearl Cotton (EPE): Widely used, it has a closed cell structure trapping air to reduce heat transfer. In lunch box style bags, it slows heat escape. However, it's not moisture resistant; wetness degrades insulation as water displaces air.

· Fiberglass and Rock Wool: Porous materials for insulation in industrial grade bags. But fiberglass can be itchy, both may release harmful particles, and they're heavy, making consumer grade bags less portable.

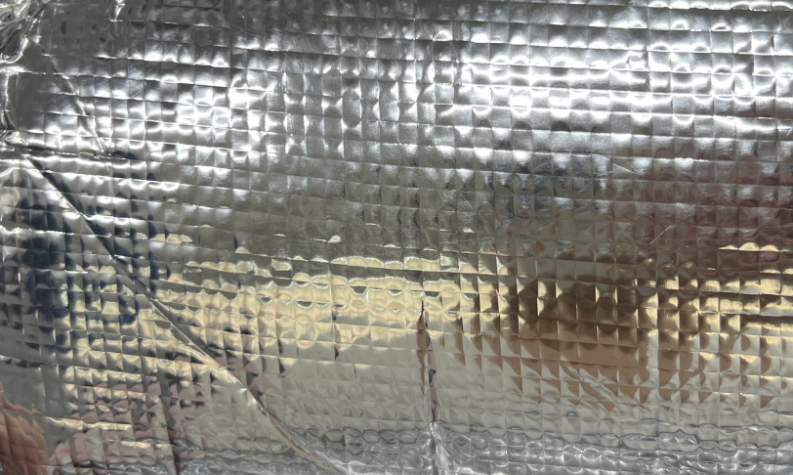

Advanced Alternatives

· Aluminum Foil and Aluminized Film: Reflect infrared radiation. Aluminum foil laminated fabric in high quality bags reflects heat back and cuts radiant loss. Aluminized film, a coated plastic, offers similar benefits and can be integrated into multi layer structures.

· Vacuum Insulated Panels (VIPs): Feature a core in a gas tight envelope with vacuum. They provide excellent insulation, though costly. Used in premium or specialized bags, like for long distance medical product transport, and their thin profile saves space.

Second, Environment - Friendly Materials

Recycled Options

· Recycled Polyester and Nylon: Made from waste like plastic bottles and fishing nets. Obaili Factory uses recycled polyester for outer layers, reducing the carbon footprint. These materials can be dyed and treated like virgin ones.

· Recycled Aluminum Foil: As effective as new in reflecting heat, it's used by Obaili Factory in inner linings, cutting environmental impact.

Biodegradable and Compostable Materials

· Biodegradable Plastics (PLA, PHA): Made from renewable resources, they break down naturally. But they need specific conditions and may not match traditional plastics in durability and insulation. Obaili Factory is researching their use.

· Natural Fibers (Cotton, Jute, Bamboo): Biodegradable and low impact. Cotton is soft, jute is strong, and bamboo has antibacterial properties. They may need treatment for water resistance and durability. Obaili Factory carefully processes them.

Third, Durability - Enhancing Materials

High - Strength Fabrics

· Nylon and Oxford Cloth: Nylon's strength and abrasion resistance suit various bag sizes. Oxford cloth, with its basket weave, adds strength. Obaili Factory uses quality versions, treating them for extra durability.

· Ballistic Nylon: A tough nylon for rugged or high value item carrying bags. Obaili Factory incorporates it in specialized designs.

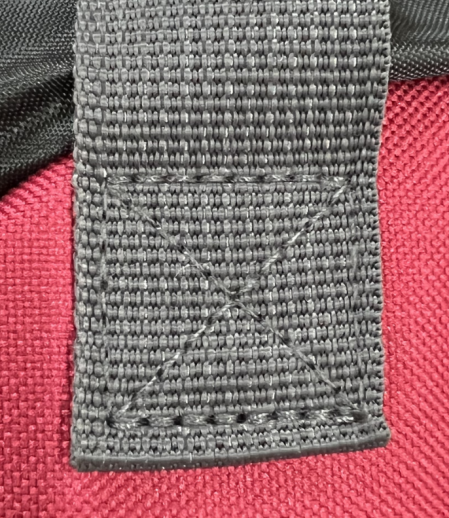

Reinforcement Elements

· Reinforced Stitching and Webbing: Obaili Factory uses double stitching and bartacking at stress points. Strong webbing for handles, securely attached, withstands heavy loads.

· Plastic and Metal Hardware: Metal zippers are more durable, and metal or strong plastic buckles and clasps keep bags secure. Coated to resist rust in wet conditions.

Finally, Waterproof Materials

Waterproof Fabrics

· Water Repellent Coated Fabrics: Fluoropolymer treated nylon and polyester make water bead and roll off. Obaili Factory applies durable coatings, though they may wear over time.

· Waterproof Membranes (Gore - Tex, TPU): Used in wet environment bags. Gore Tex allows vapor out while blocking liquid. TPU is flexible and waterproof. Obaili Factory can integrate them into bag designs.

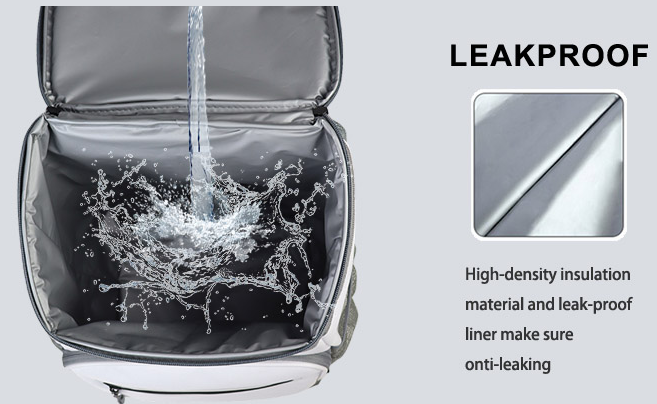

Sealing Materials

· Waterproof Zippers and Seams: Obaili Factory uses zippers with special coatings or double track designs. And the inner lining is sealed.

Obaili Factory's Edge:

First, Material Sourcing and Quality Control:Obaili sources materials from reliable suppliers, inspecting insulation, fabrics, and hardware. Our quality control tests cover insulation, durability, and waterproofing.

Second, Innovative Material Combinations: We experiment with combinations like recycled polyester, recycled aluminum foil backed foam, and biodegradable linings for better performance and sustainability.

Finally, Customization: Customers can choose from a range of materials for personalized bags, whether for personal or commercial use.

In sumary, materials determine insulated bag performance. Obaili Factory's expertise in material selection, quality control, and innovation positions it as a leader. Understanding materials helps consumers choose wisely, and enables Obaili to keep producing top notch, sustainable bags.